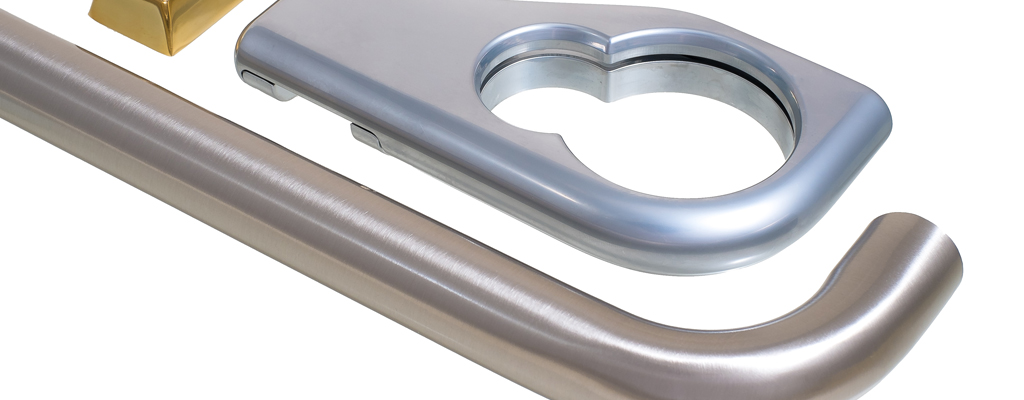

Metal Polishing

Midland Polishing & Plating Ltd offer a complete range of Metal Polishing services.

Metal Polishing is an operation necessary to prepare all metals for Electroplating that require a reasonable quality finish.

Metal Polishing comprises linishing with coarse and fine emery belts on a lathe either manually or on an automatic machine to remove abrasions, welding or brazing seams in steel, stainless steel and brass.

Porosity cold flow and split lines in either aluminium or zinc base die-castings.

Draw lines from the manufacturing in aluminium extrusions required for either anodising or electroplating.

All metals requiring polishing for satin chrome, bright chrome, and trivalent chrome, electrophoretic lacquer and aluminium finishing, need a polisher with experience and skill.

If the component is too coarsely linished it is very difficult to remove the linishing lines so the “grit” is determined by the imperfections in the material and the thickness of metal to be removed.

The “grit” can range from 80 – 400/ the lower the number the coarser the “grit,” so the higher the number the finer it is.

If a high standard is requested the polisher would start with a coarse emery belt and then linish with a finer one to remove the lines from the coarse operation,

The part would then be “buffed” or “mopped” to produce a bright finish, and in some cases the metal would be coloured off to produce a high gloss finish.

There are also different polishing compounds applied to the linishing belt to obtain a better cut and also to avoid burning the base material.

There are different compounds applied to the mop to assist the removal of the linishing lines and an additional one to finish with a high gloss.

For manual operations a solid bar compound is applied to the belt or mop but automatic machines use a liquid compound.

For more information on metal polishing, aluminium finishing, electrophoretic lacquer or electroplating contact Midland Plating & Polishing on 01902 421174 or use the contact form.