Electroplating

Midland Polishing & Plating Ltd have been electroplating since 1987and have a plethora of knowledge and experience.

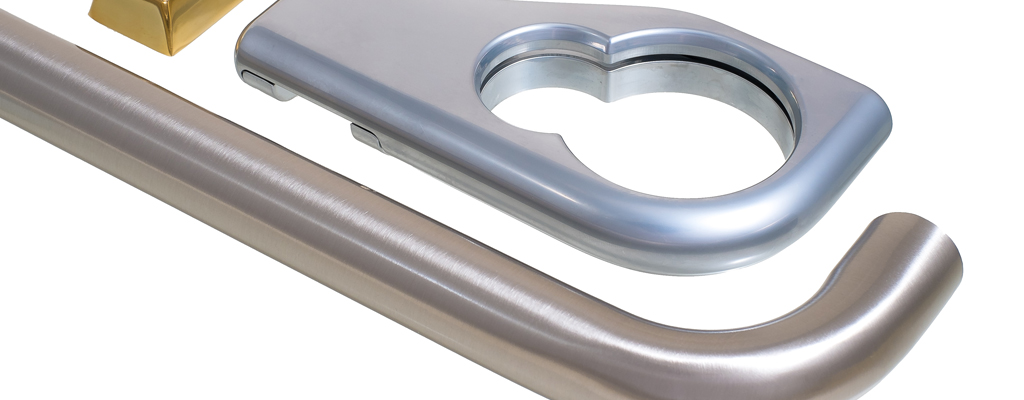

One of the reasons we electroplate satin chrome, bright chrome on steel, zinc base die-castings brass and process aluminium finishing is to protect the base material from atmospheric moisture such as salt in coastal areas and sulphide and sulphur in an industrial environment.

Some parts require metal polishing depending on individual requirements.

The electroplating process comprises an electrolyte (solution) in which a flow of current is accompanied by movement of matter, the solution must contain dissolved salts of the metal to be deposited.

EG in a nickel plating solution there is nickel sulphate for conductivity (allows the metal ions to move) nickel chloride (for dissolution of the metal bar or anode) to be deposited onto the component

An ion is a group of atoms that has gained or lost electrons and carries a positive or negative charge.

During electroplating the positive atoms are attracted to the cathode.

Electrophoretic lacquer technology works on the same principle but it uses an inert anode, the trivalent chrome process also uses an inert anode.

The anode does not dissolve in the solution.

The voltage is applied by connecting a rectifier to the anode (positive/ the metal to be deposited) and the cathode (negative/ the component for electroplating) and converts AC voltage to DC voltage.

Deep recesses and points are not suitable shapes for electroplating.

The reasons are that the metal to be plated cannot deposit into a recess easily and because chrome is less efficient than nickel the outcome is less tolerant.

Even distribution of the deposit is not possible so it is advisable to work on minimum and maximum thickness rather than actual.

For more information on electroplating contact Midland Plating & Polishing on 01902 421174 or use the contact form.