Trivalent Chrome

Midland Polishing and Plating can offer the electroplating of trivalent chrome known as Cr3+ and hexavalent chrome known as Cr6+

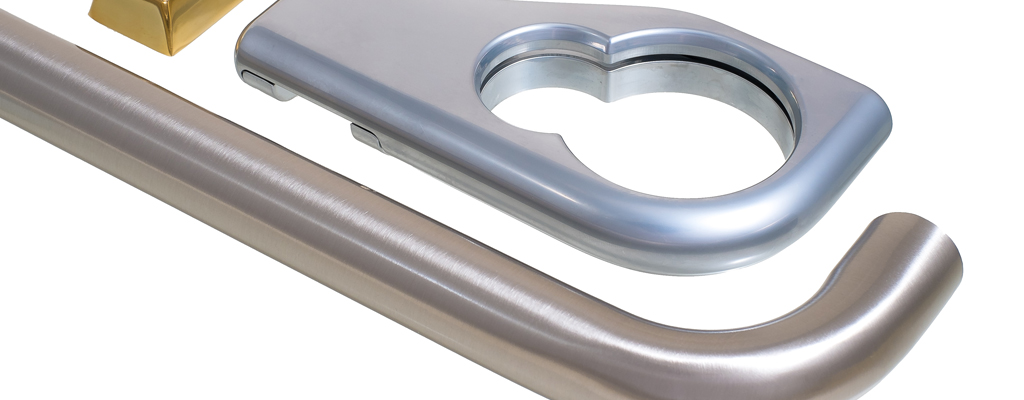

Both chrome processes are part of our aluminium finishing, satin chrome and bright chrome finishes.

Chromium plating is used for two reasons, one to prevent the nickel undercoat from tarnishing and two, to produce a hard abrasion resistant surface when the thickness is much higher for engineering purposes that sometimes requires metal polishing.

Trivalent chrome is green technology.

The thickness of the Cr3+ deposit is approximately 0.1 – 0.3 microns, in some cases 0.5 microns

The early chemistry did not produce a compatible finish to hexavalent chrome but has improved vastly over the last few years and it is difficult to see the difference with the electroplating of bright chrome.

Satin chrome is still not compatible but it does produce an aesthetic finish that is down to personal preference, this is also an area that is being investigated.

The trivalent process has superior “throwing power” in comparison to hexavalent it can cover recessed areas more readily and gives an improved uniformed thickness which avoids excessive plating on outer areas of the component, thus avoiding cracking of the deposit and burning.

Unlike nickel and copper plating but similar to electrophoretic lacquer the anode is inert and does not dissolve so the metal deposit comes from the metal salt which is part of the makeup of the solution. A chrome anode would be too brittle and expensive so either graphite or carbon electrodes are used.

For more information on Trivalent chrome, electrophoretic lacquer and electroplating contact Midland Plating & Polishing on 01902 421174 or use the contact form.